BRENWOOD LAMINATED FLOORING

BRENWOOD LAMINATED FLOORING

PRODUCT WARRANTY

• Five (5) to Ten (10) years warranty against termite resistance

• Fifteen (15) years warranty against color fade, stain and cigarette burn resistance

Products

5 Types of laminated flooring

Description

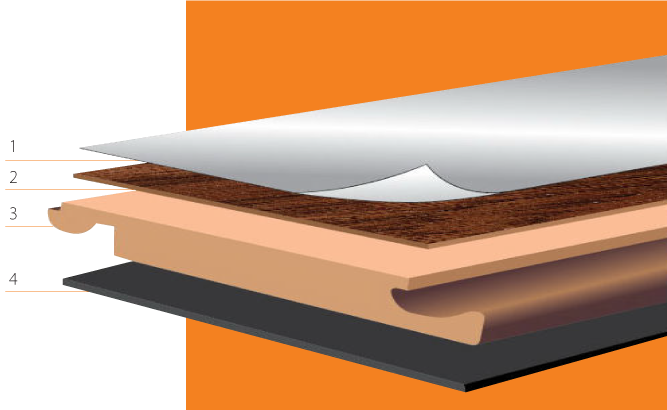

BRENWOOD laminated floorboards

are made of four (4) important

components as below:

1. Wear Layer

This is the top most surface of laminate floors. A transparent resin-based coating on the individual boards of laminate floors which is specifically designed to resist man forms of abrasion. It is typically made up of several coats of aluminum oxide that consists of millions of particles per square foot.

2. Decorative Layer

The name given to the photo rendering of the design which is made to mimic the surface of natural wood grain.

Since this layer is protected by the Wear Layer, the design will not fade, mark, or scuff.

3. Core Layer

The central layer of a laminate floor board that is the structural element supporting the weight and stresses of foot traffic.

It is made of tropical hardwood HDF

(high-density fiberboard) and is treated with paraffin wax on its edges to minimise water and other fluids from seeping onto the core layer and causing damage.

4. Stabilizing Layer

The bottom material that provides strength and stability to the laminate board preventing unnecessary

movement within the boards and also

act as a moisture barrier for the floor.

GENERAL GUIDELINES TO

FORMALDEHYDE RATING

GENERAL GUIDELINES TO

FORMALDEHYDE RATING

Formaldehyde is a colourless gas with a pungent, irritating odour.

It is used in the production of resins that act as glues for wood

products, pulp, paper, glasswool and rockwool.

Emission level of E0 and E1 are equivalent to those set forth by the

U.S. Department of Labor Occupational Safety & Health Administration

(OSHA) and also meet the European and Australian guideline on

formaldehyde emission level. Hence, laminate floors that are under

E0 and E1 are generally recognized as eco–friendly.

Formaldehyde is a colourless gas with a pungent, irritating odour. It is used in the production of resins that act as glues for wood products, pulp, paper, glasswool and rockwool.

Emission level of E0 and E1 are equivalent to those set forth by the

U.S. Department of Labor Occupational Safety & Health Administration (OSHA) and also meet the European and Australian guideline on formaldehyde emission level. Hence, laminate floors that are under E0 and E1 are generally recognized as eco–friendly.

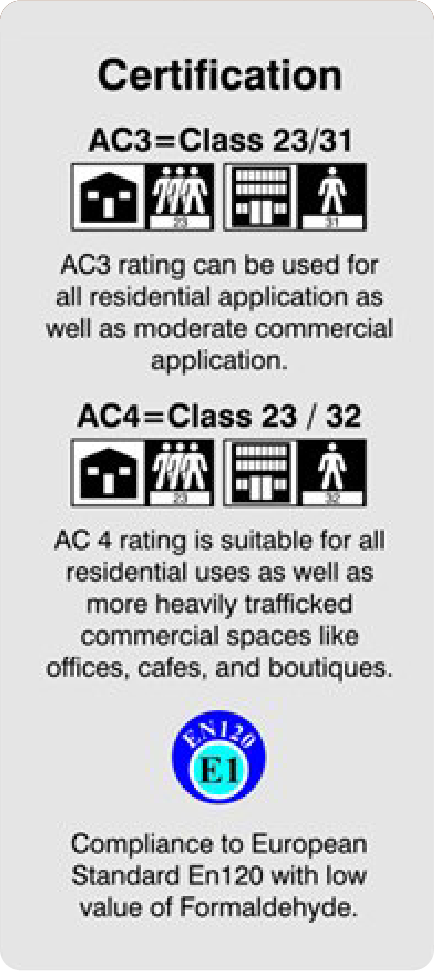

GENERAL GUIDELINES

TO AC RATING

GENERAL GUIDELINES TO

FORMALDEHYDE RATING

An understanding of AC ratings and knowledge of the traffic pattern

of the laminated flooring installation location would enable user to

choose the appropriate laminated flooring material. Below are the

various AC ratings with its intended usage:

An understanding of AC ratings and knowledge of the traffic pattern of the laminated flooring installation location would enable user to choose the appropriate laminated flooring material. Below are the various AC ratings with its intended usage:

ADVANTAGES